ABOUT US

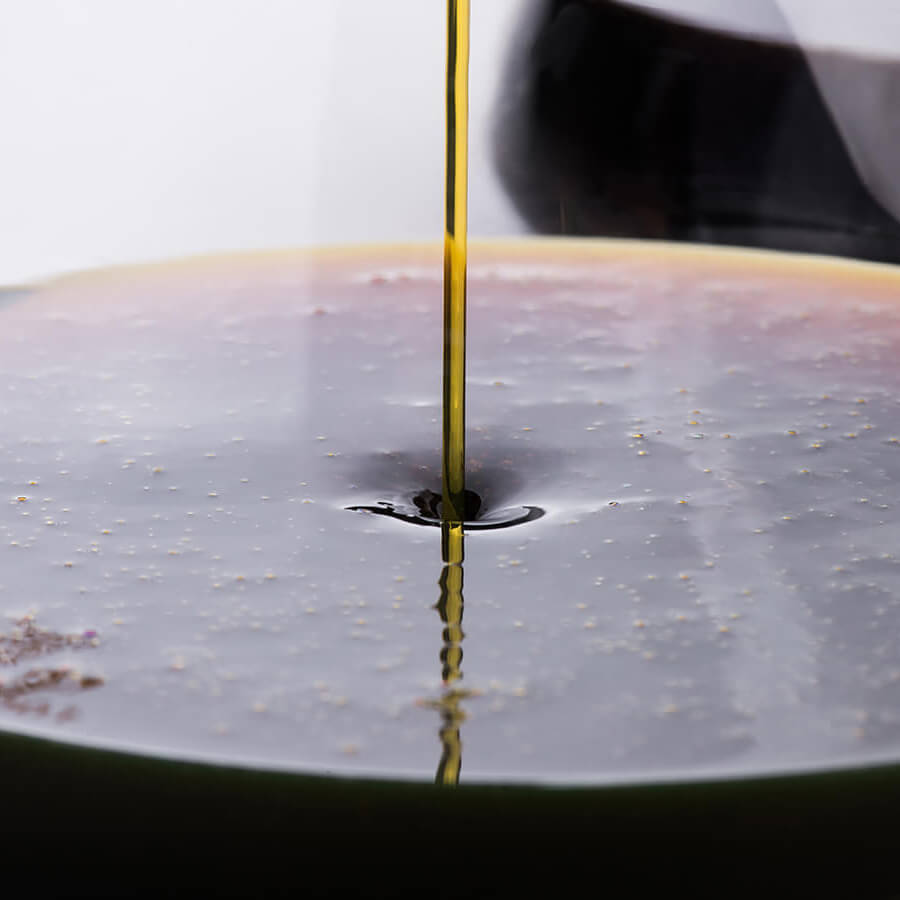

The largest producer of green RPO (rubber process oils) and highly aromatic additives for rubber compounds in South-East Asia

- The company possesses advanced technologies and utilizes them to create top-tier products that provide exceptional user performance

- With its strategic geographic location and cost-efficient logistics, NPOMP establishes itself as a reliable and effective supplier for customers across Asia, the Middle East, and Europe

- The company possesses advanced technologies and utilizes them to create top-tier products that provide exceptional user performance

- With its strategic geographic location and cost-efficient logistics, NPOMP establishes itself as a reliable and effective supplier for customers across Asia, the Middle East, and Europe

CORE BUSINESS

The NPOMP production facility takes advantage of its prime location within Tanjung Langsat, Malaysia — a thriving port-integrated industrial zone — to ensure streamlined operations and enhanced logistical capabilities

- By leveraging the advantages of both petroleum-based and bio-based (fully renewable) raw materials, the company delivers a diverse set of options to customers in its RPO product line01

- Our products are selected by leading tire and rubber manufacturers for their environmentally-friendly characteristics and superior performance that meets the demands of end-users02

- Some of our end products have a wide range of applications, being utilized as components of fuel oils or as raw materials in bitumen and pavement production and in roofing and insulation materials manufacturing03

- The backbone of NPOMP’s green RPO production process is its unique proprietary selective feedstock components treatment technology.04

- The company maintains its high standards of end product quality control through its dedicated and proficient in-house laboratory05

- By leveraging the advantages of both petroleum-based and bio-based (fully renewable) raw materials, the company delivers a diverse set of options to customers in its RPO product line01

- Our products are selected by leading tire and rubber manufacturers for their environmentally-friendly characteristics and superior performance that meets the demands of end-users02

- Some of our end products have a wide range of applications, being utilized as components of fuel oils or as raw materials in bitumen and pavement production and in roofing and insulation materials manufacturing03

- The backbone of NPOMP’s green RPO production process is its unique proprietary selective feedstock components treatment technology.04

- The company maintains its high standards of end product quality control through its dedicated and proficient in-house laboratory05

The company is certified according to ISO 9001, ISO 45001, ISO 14001 and has adopted elements of the industrial standard IATF16949 into its production system

The company is certified according to ISO 9001, ISO 45001, ISO 14001 and has adopted elements of the industrial standard IATF16949 into its production system

Products

Products

NORMAN 346 TDAE

Process oil NORMAN 346 TDAE is the aromatic oil with a standardized content of polycyclic aromatic hydrocarbons

Packing — road tanks, vessel, ISO containers, IBC containers

Shelf life — 24 month

Basic quality parameters set out in Table

Shelf life — 24 month

Basic quality parameters set out in Table

Physical Properties

Density (20°C), kg/m3

Kinematic viscosity (100°C), cSt

Aniline point, wt.%

Ca, % min

Pour point, °C

Flash point, COC, °C

Water content, v/v.%

Density (20°C), kg/m3

Kinematic viscosity (100°C), cSt

Aniline point, wt.%

Ca, % min

Pour point, °C

Flash point, COC, °C

Water content, v/v.%

NORMAN 346

927-967

16-23

64-75

25

< 30

> 220

0.03

927-967

16-23

64-75

25

< 30

> 220

0.03

The contents of benso (a)pyrene and sum of individual PAHs, named in EC No 1907/2006, US EPA and AfPS GS 2014:01 PAK, in NORMAN 346 oil does not exceed 1 mg/kg and 10 mg/kg, respectively. Thus the product fully complies with the requirements of Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), including provisions of the Commission Regulation (EC) No 1272/2013 of 6 December 2013 and Commission Regulation (EC) No 2015/326 of 2 March 2015.

Application

Extender oil of synthetic rubbers and as a plasticizer of rubber compounds for tire, rubber goods, as a plasticizer for sealants and bitumen, in the production of carbon black and polymer sulfur to reduce dusting.

Application

Extender oil of synthetic rubbers and as a plasticizer of rubber compounds for tire, rubber goods, as a plasticizer for sealants and bitumen, in the production of carbon black and polymer sulfur to reduce dusting.

NORMAN 132

895-925

13-17

85-100

11-17

< 0

> 230

0.03

895-925

13-17

85-100

11-17

< 0

> 230

0.03

NORMAN 132 MES

Process oil NORMAN 132 MES is the aromatic oil with a standardized content of polycyclic aromatic hydrocarbons

Packing – road tanks, vessel, ISO containers, IBC containers

Shelf life – 24 month

Basic quality parameters set out in Table

Shelf life – 24 month

Basic quality parameters set out in Table

Physical Properties

Density (20°C), kg/m3

Kinematic viscosity (100°C), cSt

Aniline point, wt.%

Ca, %

Pour point, °C

Flash point, COC, °C

Water content, v/v.%

Density (20°C), kg/m3

Kinematic viscosity (100°C), cSt

Aniline point, wt.%

Ca, %

Pour point, °C

Flash point, COC, °C

Water content, v/v.%

The contents of benso (a)pyrene and sum of individual PAHs, named in EC No 1907/2006, US EPA and AfPS GS 2014:01 PAK, in NORMAN 123 oil does not exceed 1 mg/kg and 10 mg/kg, respectively. Thus the product fully complies with the requirements of Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), including provisions of the Commission Regulation (EC) No 1272/2013 of 6 December 2013 and Commission Regulation (EC) No 2015/326 of 2 March 2015.

Application

Plasticizer of rubber compounds for winter tire, improving snow and ice grip. Plasticizer for rubber goods, as a plasticizer for sealants and bitumen, in the production of carbon black and polymer sulfur to reduce dusting.

Application

Plasticizer of rubber compounds for winter tire, improving snow and ice grip. Plasticizer for rubber goods, as a plasticizer for sealants and bitumen, in the production of carbon black and polymer sulfur to reduce dusting.

PLASTOIL

RUBBER PROCESS OIL

Guaranteed storage period – 24 months

Packing – ISO containers, tank trucks, vessels.

Packing – ISO containers, tank trucks, vessels.

Parameter

Density (20°C), kg/m3

Kinematic viscosity (100°C), cSt

Aniline point, wt.%

Pour point, °C

Flash point, COC, °C

Water content, v/v.%

Density (20°C), kg/m3

Kinematic viscosity (100°C), cSt

Aniline point, wt.%

Pour point, °C

Flash point, COC, °C

Water content, v/v.%

Min

1000

20

—

—

220

—

1000

20

—

—

220

—

Plastoil is high aromatic oil that might be applied as a rubber process oil or a plasticizer for polymer modified bitumens

Max

—

34

60

35

—

0.1

—

34

60

35

—

0.1

Test methods

ASTM D 1298

ASTM D 445

ASTM D 611

ASTM D 97

ASTM D 92

ASTM D 95

ASTM D 1298

ASTM D 445

ASTM D 611

ASTM D 97

ASTM D 92

ASTM D 95

Min-max values

70 – 200

1,000 – 8,000

max 1,200

< 36

min 230

< 0.1

70 – 200

1,000 – 8,000

max 1,200

< 36

min 230

< 0.1

TFOE-80

High aromatic petroleum product. TFOE-80 is completely free of saturated paraffinic and naphthenic hydrocarbons

Guaranteed storage period – 24 months

Packing – ISO containers, tank trucks, vessels.

Packing – ISO containers, tank trucks, vessels.

Parameter

Kinematic viscosity (100°C), cSt

Kinematic viscosity (60°C), cSt

Density (15°C), kg/m3

Pour point, °C

Flash point, °C

Water content

Kinematic viscosity (100°C), cSt

Kinematic viscosity (60°C), cSt

Density (15°C), kg/m3

Pour point, °C

Flash point, °C

Water content

Application

- Plasticizer for polymer-bitumen materials and a viscosity corrector for thick and very viscous bitumen grades

- Raw material for carbon black

Test methods

ASTM D 4052

ASTM D 445

ASTM D 445

ASTM D 97

ASTM D 92

ASTM D 4294

ASTM D 95

ASTM D 482

ISO 10370

ASTM D 4052

ASTM D 445

ASTM D 445

ASTM D 97

ASTM D 92

ASTM D 4294

ASTM D 95

ASTM D 482

ISO 10370

80M (L-VGO)

Guaranteed storage period – 24 months

Packing – ISO containers, tank trucks, vessels.

Packing – ISO containers, tank trucks, vessels.

Parameter

Density at 15°С, kg/m3

Kinematic viscosity (100°С), mm2/s

Kinematic viscosity (50°С), mm2/s

Pour point, °C

Flash point, COC, °C

Total sulfur content, wt.%

Water content, v/v.%

Ash content, wt.%

Carbon residue micro, wt.%

Density at 15°С, kg/m3

Kinematic viscosity (100°С), mm2/s

Kinematic viscosity (50°С), mm2/s

Pour point, °C

Flash point, COC, °C

Total sulfur content, wt.%

Water content, v/v.%

Ash content, wt.%

Carbon residue micro, wt.%

Min

1060

35

1400

—

100

—

—

—

—

1060

35

1400

—

100

—

—

—

—

80M (L-VGO) is an oil that might be applied as a component of marine residual fuel oil of the RMB 30 grade or as a component of light fuel oils for industrial equipment.

Max

1095

55

3600

33

—

5.5

0.1

0.03

4.99

1095

55

3600

33

—

5.5

0.1

0.03

4.99

Contact us

Mohd Saiful Nizam Bin Mansor / Head of Supply Chain

Yeo Seuk Yun / HR & Admin Manager

Norman Process Oils Malaysia Plant Sdn Bhd

PLO 13, Jalan Tengar, Kompleks Perindustrian Tanjung Langsat, 81700 Pasir Gudang, Johor

Tel: +60 7259 9000

npomp@npomp.com

Yeo Seuk Yun / HR & Admin Manager

Norman Process Oils Malaysia Plant Sdn Bhd

PLO 13, Jalan Tengar, Kompleks Perindustrian Tanjung Langsat, 81700 Pasir Gudang, Johor

Tel: +60 7259 9000

npomp@npomp.com

Contact us

Mohd Saiful Nizam Bin Mansor / Head of Supply Chain

Yeo Seuk Yun / HR & Admin Manager

Norman Process Oils Malaysia Plant Sdn Bhd

PLO 13, Jalan Tengar, Kompleks Perindustrian Tanjung Langsat, 81700 Pasir Gudang, Johor

Tel: +60 7259 9000

npomp@npomp.com

Yeo Seuk Yun / HR & Admin Manager

Norman Process Oils Malaysia Plant Sdn Bhd

PLO 13, Jalan Tengar, Kompleks Perindustrian Tanjung Langsat, 81700 Pasir Gudang, Johor

Tel: +60 7259 9000

npomp@npomp.com

We use cookies to provide the best site experience.